Multi-Skill App

Introduction

Section titled “Introduction”The Multi-Skill application is designed to track operator performance across different machines, operations, and styles. It provides detailed cycle time analysis with lap timing functionality for continuous improvement.

Key Features

Section titled “Key Features”- Operator skill level tracking

- Machine operation performance monitoring

- Lap timing system for cycle time analysis

- Critical operation identification

- Real-time performance dashboard

User Interface Components

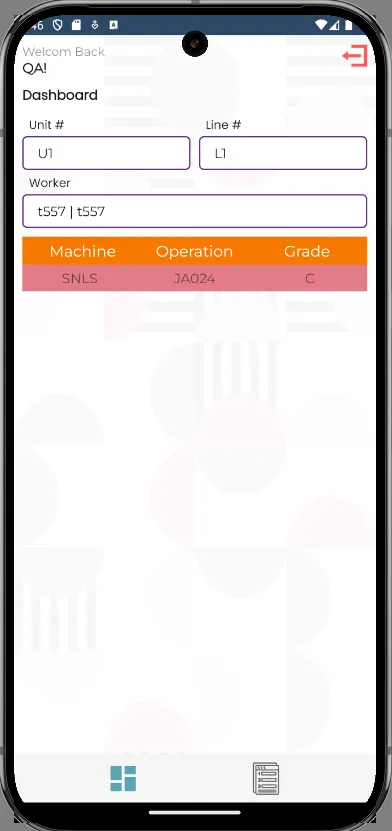

Section titled “User Interface Components”Dashboard

Section titled “Dashboard”

The dashboard displays:

- Current user (QA in this case)

- Unit and Line information (UI | L1)

- Worker ID (t557)

- Current machine assignment:

- Machine type (SNLS)

- Operation code (JA024)

- Skill grade (C)

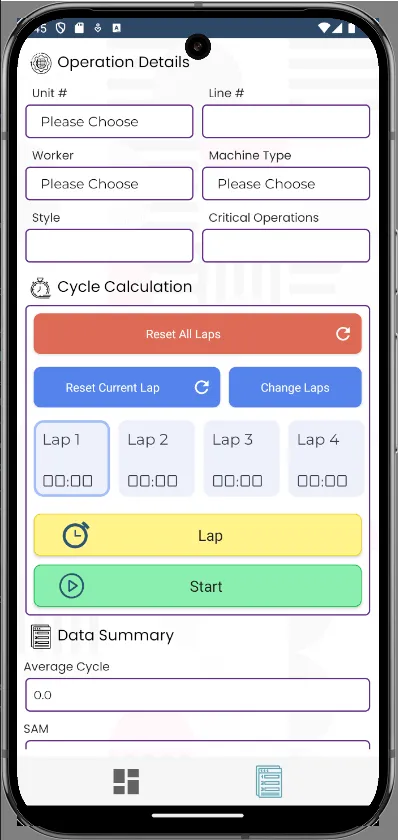

Operation Details & Lap Tracking

Section titled “Operation Details & Lap Tracking”

Operation Configuration

Section titled “Operation Configuration”- Unit and Line selection (dropdown)

- Worker selection (dropdown)

- Machine Type selection (dropdown)

- Style information

- Critical operations tracking

Lap Timing System

Section titled “Lap Timing System”-

Reset Controls:

- Reset All Laps (clears all lap times)

- Reset Current Lap (clears only the active lap)

- Change Laps (modifies number of available laps)

-

Lap Management:

- Displays up to 4 laps (configurable)

- Shows current time for each lap (0:00 initially)

- “Lap” button to record current lap time

- “Start” button to begin timing

-

Data Summary:

- Average Cycle time calculation (0.0 initially)

- SAM (Standard Allowed Minutes) metric

Functional Specifications

Section titled “Functional Specifications”Lap Management System

Section titled “Lap Management System”-

Adding Laps:

- User can increase available laps by clicking “Change Laps”

- System dynamically adds new lap fields (Lap 5, Lap 6, etc.)

-

Timing Operations:

- Click “Start” to begin the first lap timer

- Click “Lap” to:

- Record current lap time

- Start timing the next lap automatically

- Visual indication shows which lap is currently active

-

Resetting Laps:

- “Reset Current Lap” clears only the active lap timer

- “Reset All Laps” clears all recorded times and resets the system

Performance Tracking

Section titled “Performance Tracking”- System calculates:

- Individual lap times

- Average cycle time across all laps

- Compares against SAM (Standard Allowed Minutes)

- Tracks operator grade progression

- Monitors performance on critical operations

Usage Scenarios

Section titled “Usage Scenarios”-

New Operation Setup:

- Operator selects their Unit/Line

- Chooses machine type and operation

- Identifies if operation is critical

-

Cycle Time Analysis:

- Starts timing with “Start” button

- Records consecutive laps with “Lap” button

- Reviews average cycle time against standards

-

Skill Development:

- Tracks performance across different machine types

- Monitors grade improvements over time

- Identifies areas needing improvement via lap analysis

Technical Notes

Section titled “Technical Notes”- Lap data is stored locally during session

- System supports unlimited laps (UI shows 4 by default)

- All time calculations are in minutes:seconds format

- Average cycle time updates in real-time after each lap