Sewing Line Tracking

Overview

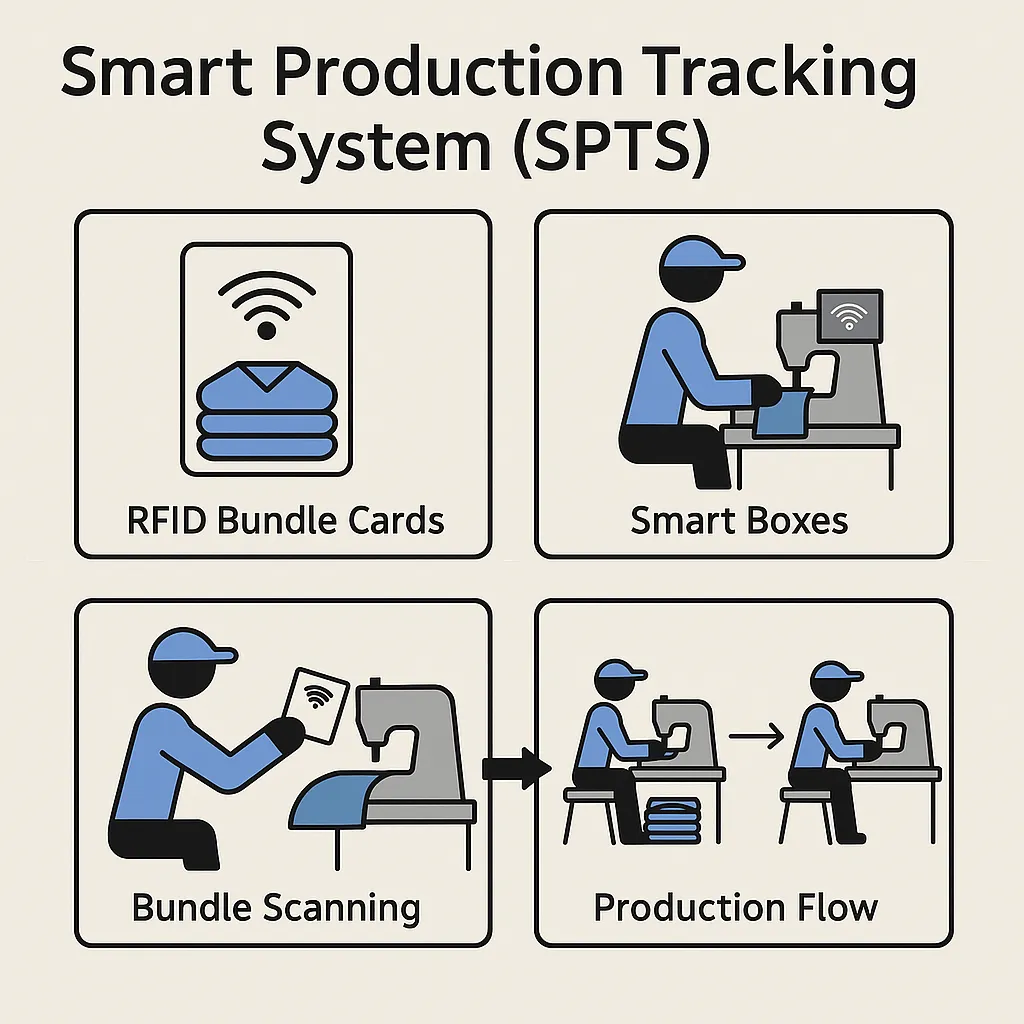

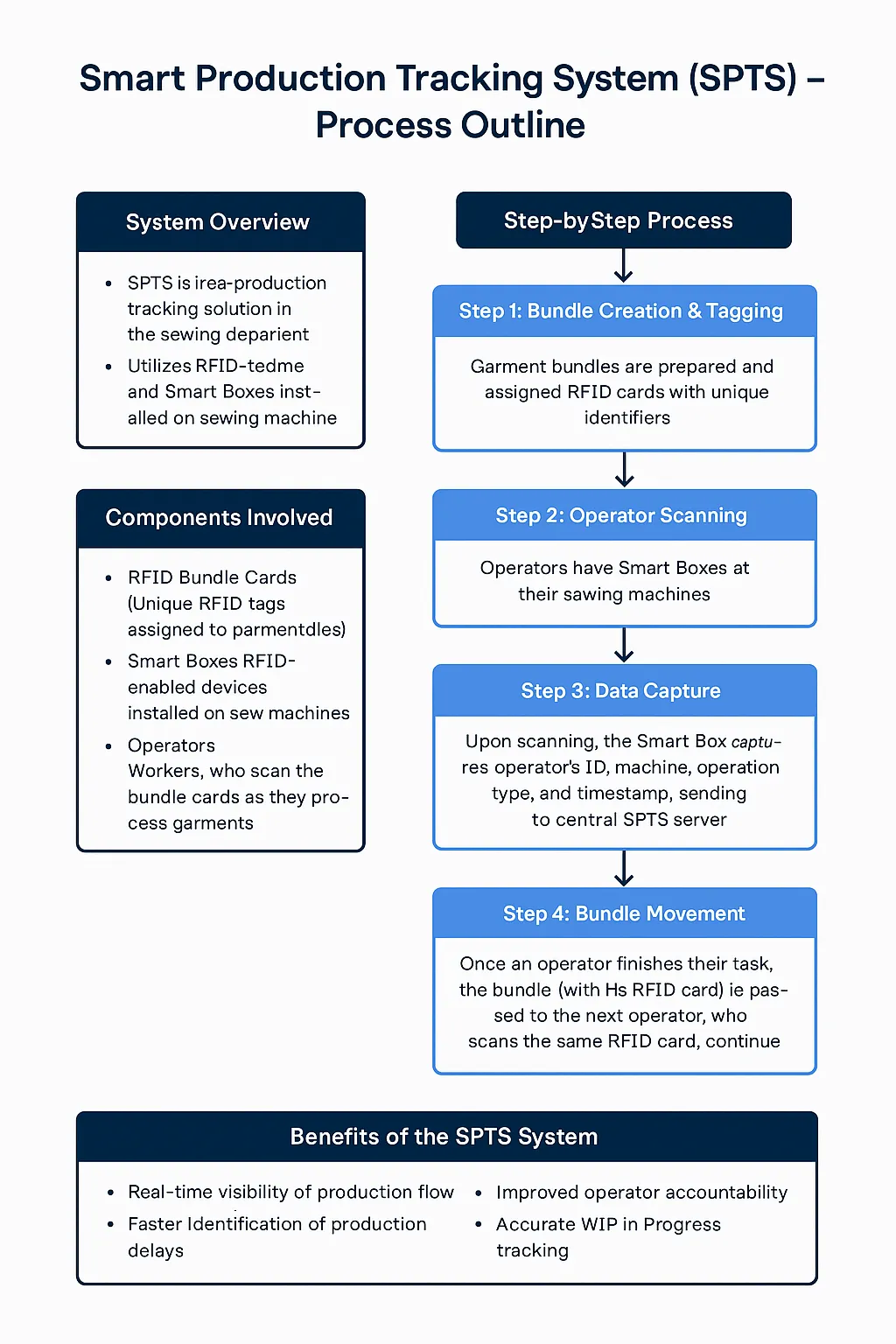

Section titled “Overview”- SPTS is a real-time production tracking solution used in the sewing department.

- It uses RFID technology and Smart Boxes installed on individual sewing machines.

- The system ensures live visibility of garment production progress across all operations.

Components

Section titled “Components”- RFID Bundle Cards: Unique RFID tags assigned to each garment bundle.

- Smart Boxes: RFID-enabled devices installed on sewing machines.

- Operators: Workers who scan the bundle cards as they process the garments.

- SPTS Server & Dashboard: Backend system that receives, stores, and displays real-time production data.

Step-by-Step Process

Section titled “Step-by-Step Process”-

Bundle Creation & Tagging:

Garment bundles are prepared and assigned RFID cards with unique identifiers.

-

Operator Scanning:

Each operator has a Smart Box at their sewing machine.

When an operator starts working on a bundle, they scan the RFID card on the Smart Box.

-

Data Capture:

Upon scanning, the Smart Box captures the operator’s ID, machine, operation type, and timestamp.

This information is sent to the central SPTS server.

-

Bundle Movement:

Once the operator finishes their task, the bundle (with the RFID card) is passed to the next operator.

The next operator scans the same RFID card, and the process continues through the production line.

-

Real-Time Tracking

Each scan updates the production status on the SPTS Dashboard in real-time.

Supervisors and managers can view:

- Current operation stage of each bundle

- Operator-wise production

- Bottlenecks and idle time

- Overall line efficiency

-

Benefits of the SPTS System

- Real-time visibility of production flow

- Improved operator accountability

- Faster identification of production delays

- Accurate WIP (Work In Progress) tracking

- Data-driven decisions for line balancing and planning

Process Outline

Section titled “Process Outline”

System Flow

Section titled “System Flow”