Paper-based Information Tracking

Overview

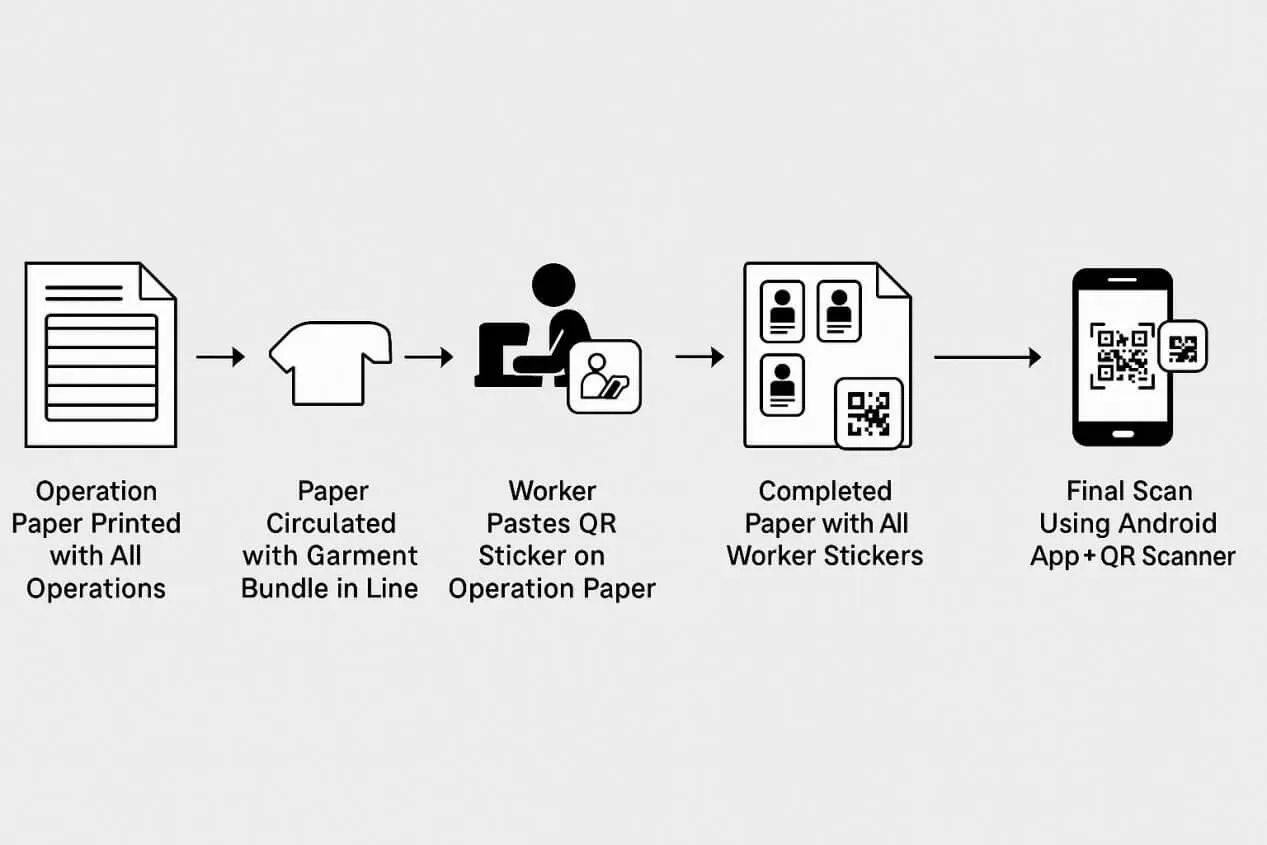

Section titled “Overview”The Paper-based Information Tracking System (PITS) is a semi-digital module designed to track garment production and map worker activity.

PITS uses a physical operation paper and worker identity stickers with QR codes.

It enables simplified traceability in environments where fully electronic tracking may not be feasible.

Components

Section titled “Components”-

Operation Paper:

A printed sheet listing all operations required for the garment bundle.

-

Worker QR Stickers:

Each worker has a unique sticker containing their name, ID, and a QR code with encoded identity information.

-

Android App with Scanner:

Used at the end of the line to scan the operation paper and digitize bundle progress and worker mapping.

Step-by-Step Process

Section titled “Step-by-Step Process”-

Operation Paper Distribution:

A printed operation paper is created for each garment bundle.

This paper lists all operations to be performed in the line.

-

Operator Scanning:

Each operator has a Smart Box at their sewing machine.

When an operator starts working on a bundle, they scan the RFID card on the Smart Box.

-

Worker Sticker Pasting:

As the paper circulates with the bundle, each operator pastes their QR sticker against the operation they are performing.

The paper is then passed along to the next worker in the sequence.

-

Bundle Movement:

Once the operator finishes their task, the bundle (with the RFID card) is passed to the next operator.

The next operator scans the same RFID card, and the process continues through the production line.

-

Digital Mapping

- The system reads the QR codes from the paper and:

- Maps worker details to each operation

- Updates the production status of the bundle

- Saves all data in the central system for reporting and analysis

Benefits

Section titled “Benefits”- Cost-effective tracking in lines without smart hardware

- Maintains full visibility of operator involvement

- Seamless integration with digital systems via app scanning

- Eliminates manual data entry at the end of production

- Enables post-line productivity and quality analysis

Process Outline

Section titled “Process Outline”