Carton Audit

The Carton Audit Module is designed to ensure accuracy and compliance in the packing and shipping process.

It provides a systematic process for verifying packed carton contents and then accepting or rejecting the carton.

This module helps reduce shipping errors, improves traceability, and supports quality assurance by maintaining detailed audit trails for every carton leaving the facility.

Pre-Requisites

Section titled “Pre-Requisites”For a pre-pack to be available for audit, the following conditions must be met:

-

It’s Pack Job must be finished

- In

[Packing].[PackJob],JobStatusmust beCompleted

- In

-

The logged-in user must have the required permissions

-

Packing list should not have passed audit already

- In

[Packing].[PrePackingList],PackStatusmust bePackingCompleted

- In

-

There is no audit in progress

- In

[Packing].[CartonAuditSession], there is no audit against the pre-pack withAuditStatusofPending

- In

-

Packing list must not be shipped

- In

[Packing].[PrePackingList],PackStatusmust not bePackingCompleted - Doesn’t actually need to be checked since check #3 already checks for this

- In

-

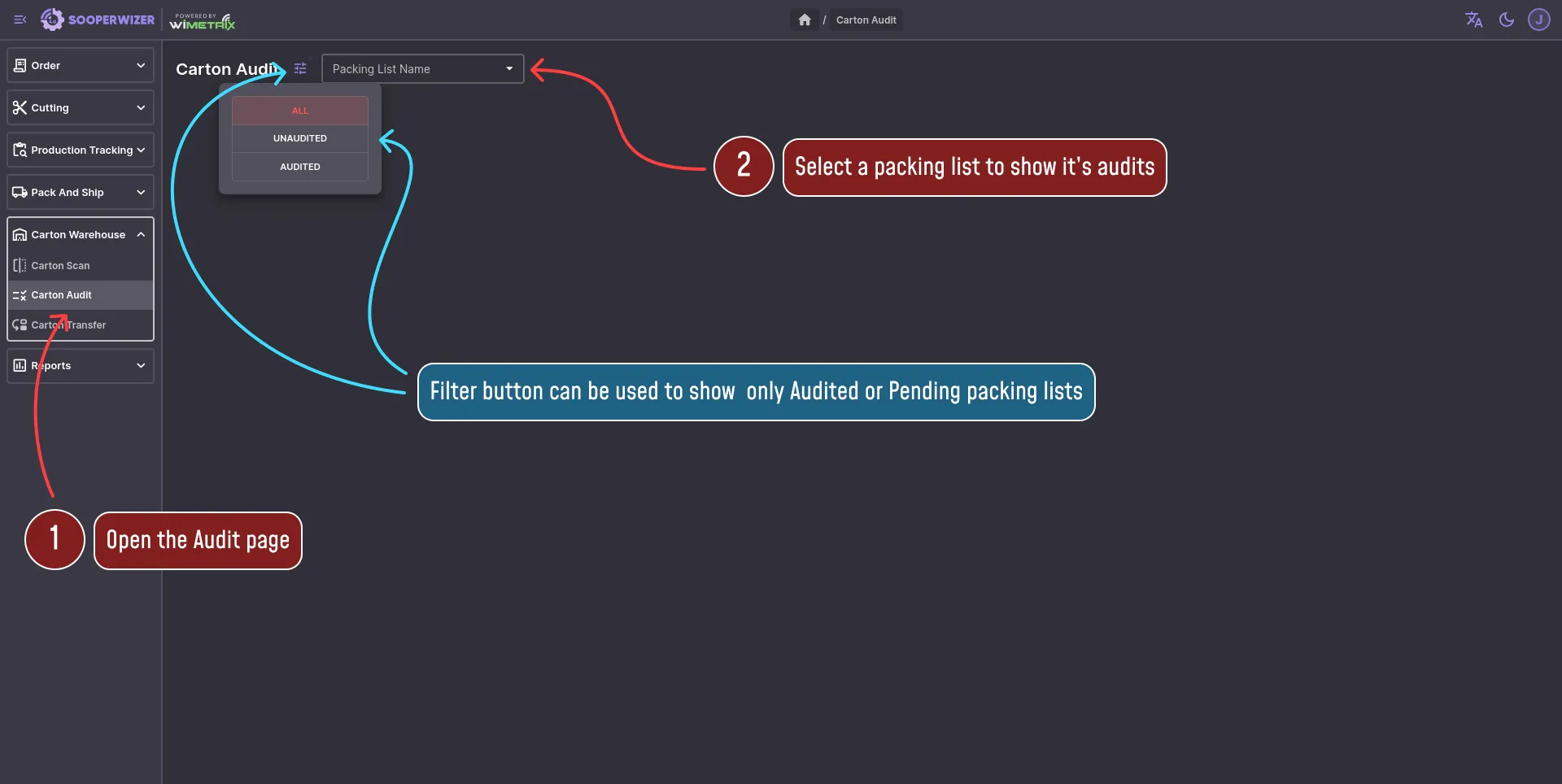

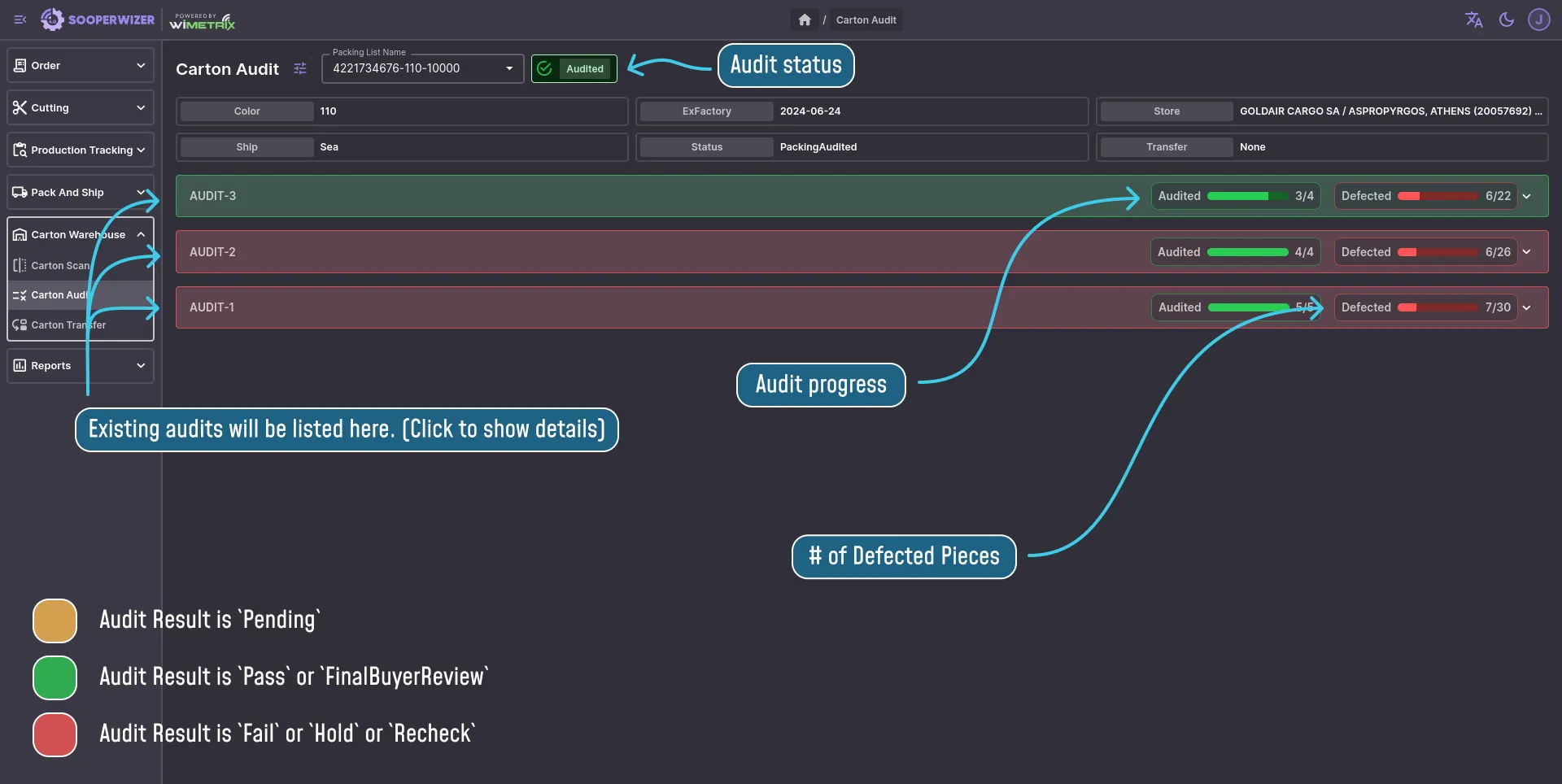

Select a Pre-pack to audit.

- All existing audits will be listed

- User can explore existing audit details

- In-progress audits can be updated

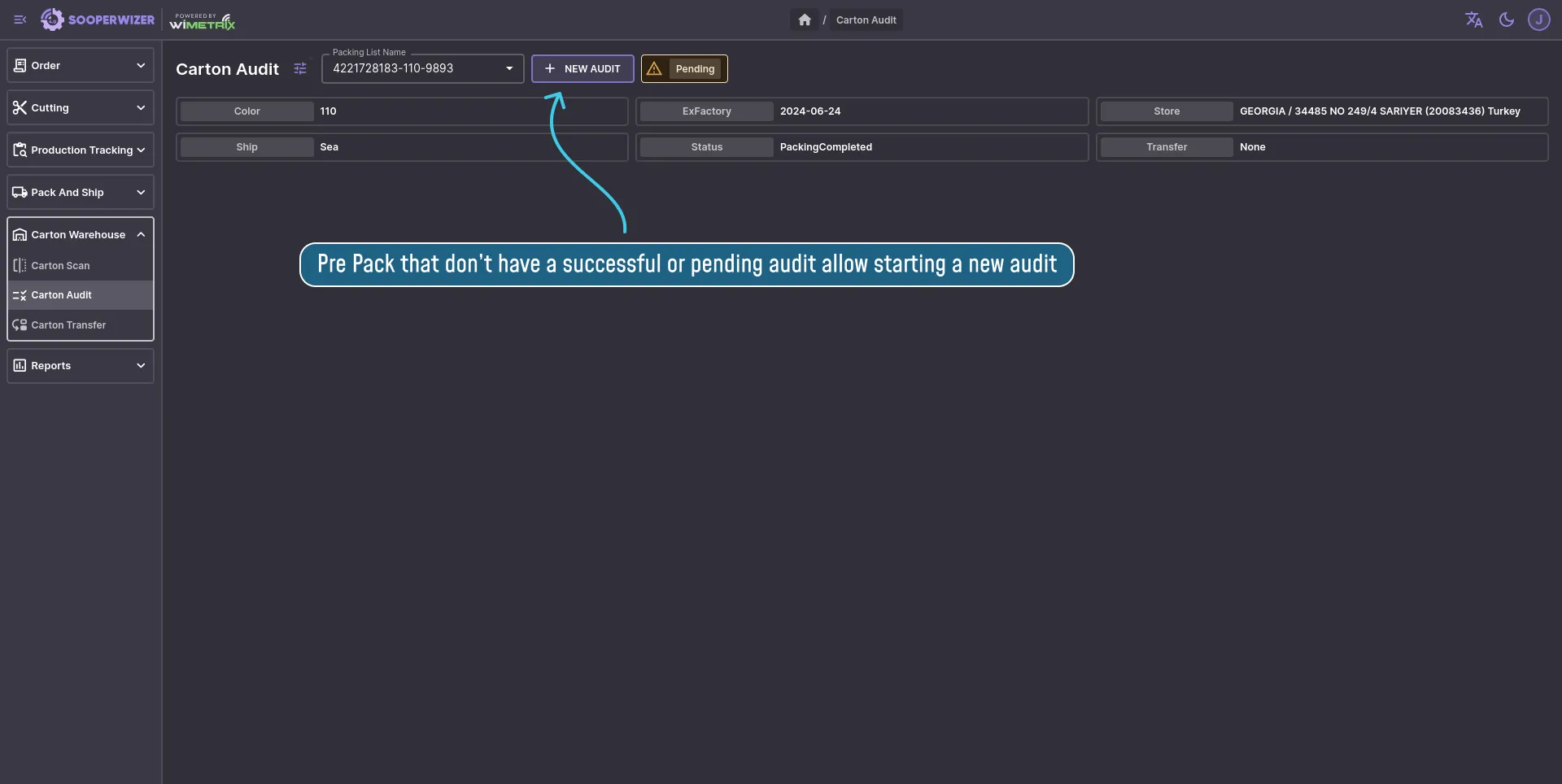

- New audits can be created if there is no in-progress or successful audit

-

Click the new audit button.

- In

CartonAuditSession, A new empty audit will be createdSessionNamewill be set toAUDIT-{AuditNo}__{PrePackingListName}AuditStatuswill be set toPending

- In

CartonAuditSessionDetail, an entry will be created for each size- Default

SampleSizeQuantitywill be calculated for each size

- Default

- Default

DefectedQuantitywill be set to0 - In

CartonAuditLog- cartons will be auto selected based on required audits for each size

- Entries will be created for each carton with default

Passstatus and without any faults or defects

- In

-

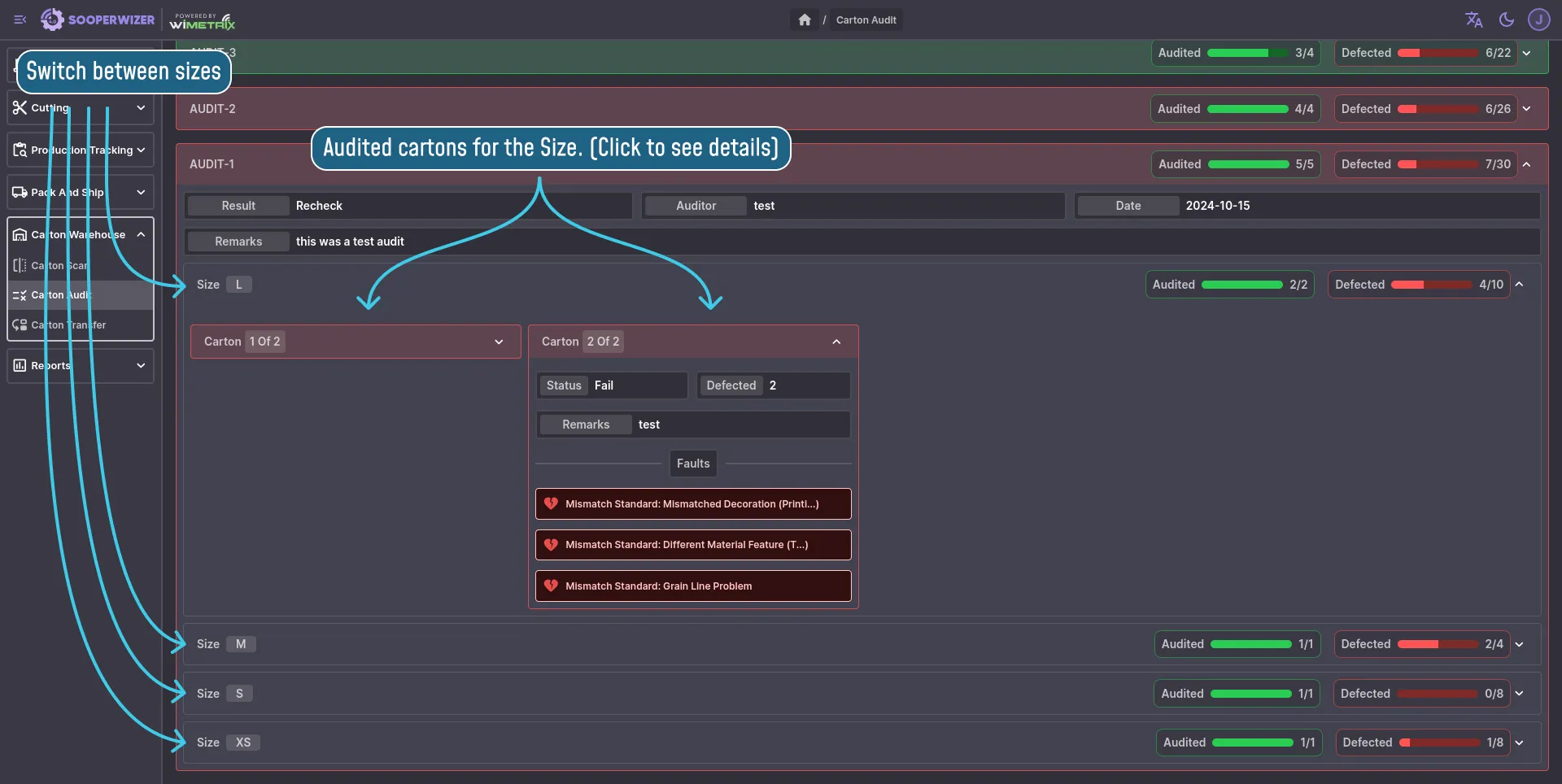

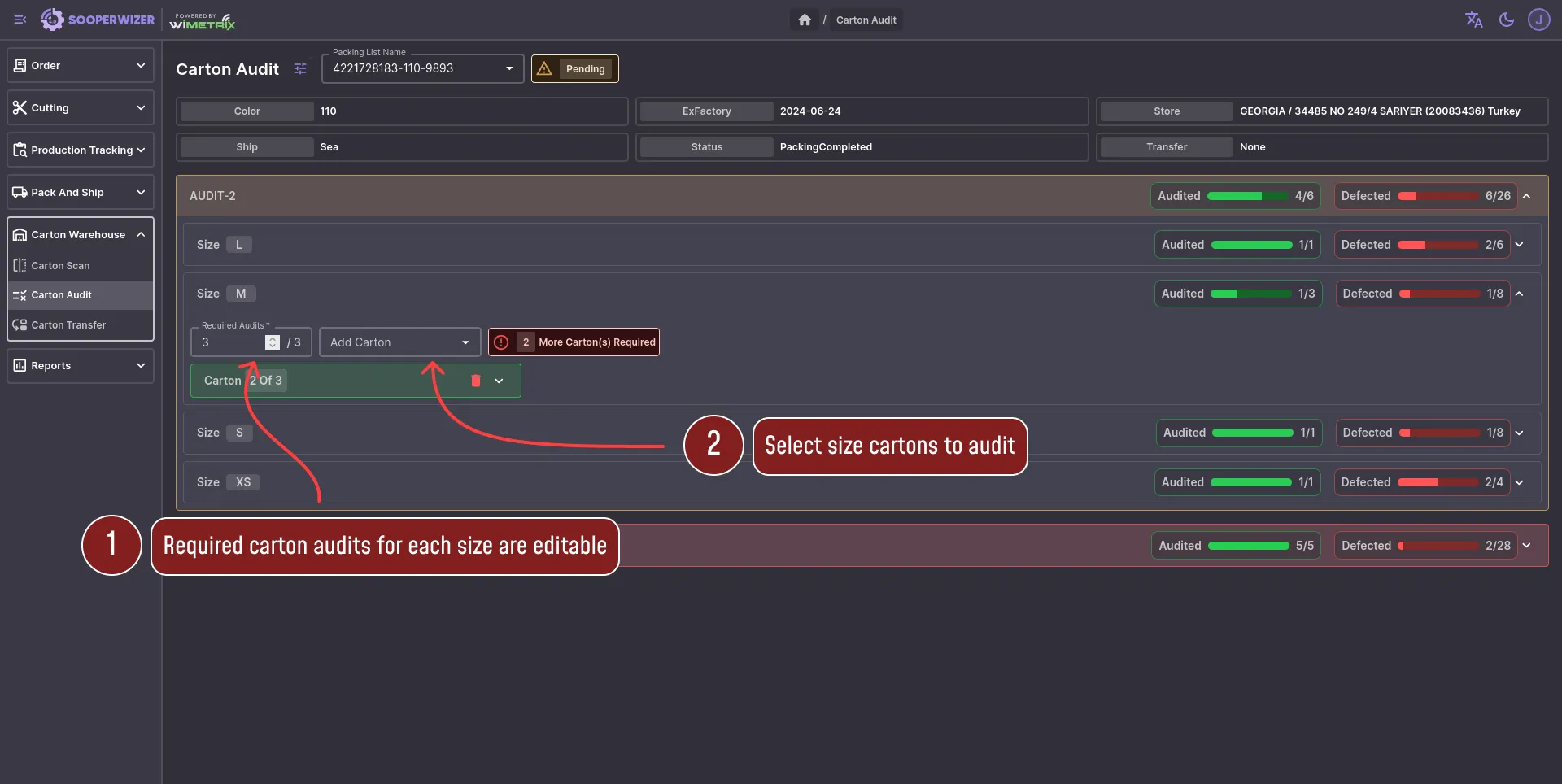

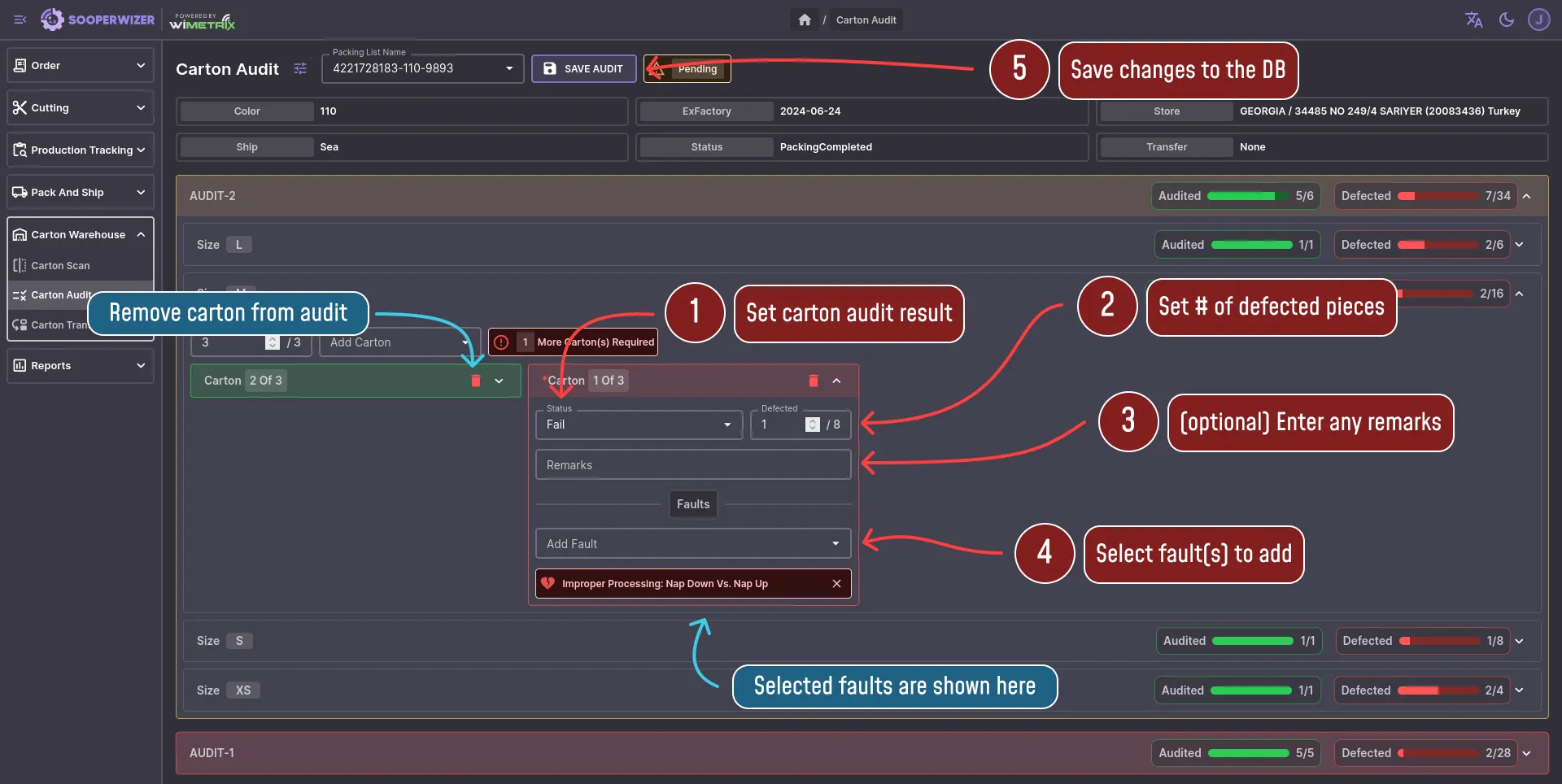

Add and update audit details. (Audit detail can be saved at any time)

- (Optional) Update

SampleSizeQuantitycan be updated for each size - Select the required number of cartons to audit for each size

- In

CartonAuditLog, an entry is created for each carton

- In

- (Optional) Set the defected piece quantity for each carton

- In

CartonAuditLog,DefectedQuantityis updated - In

CartonAuditSessionDetail,DefectedQuantityis updated

- In

- (Optional) Select one or more fault found for each carton

- In

CartonAuditFaultLog, an entry is made for each fault

- In

- (Optional) Add additional remarks for each carton

- In

CartonAuditLog,Remarksis updated

- In

- Set audit result status for each carton

- Result must not be

Pendingfor any carton for the audit to finish - In

CartonAuditLog,AuditStatusis updated

- Result must not be

- (Optional) Update

-

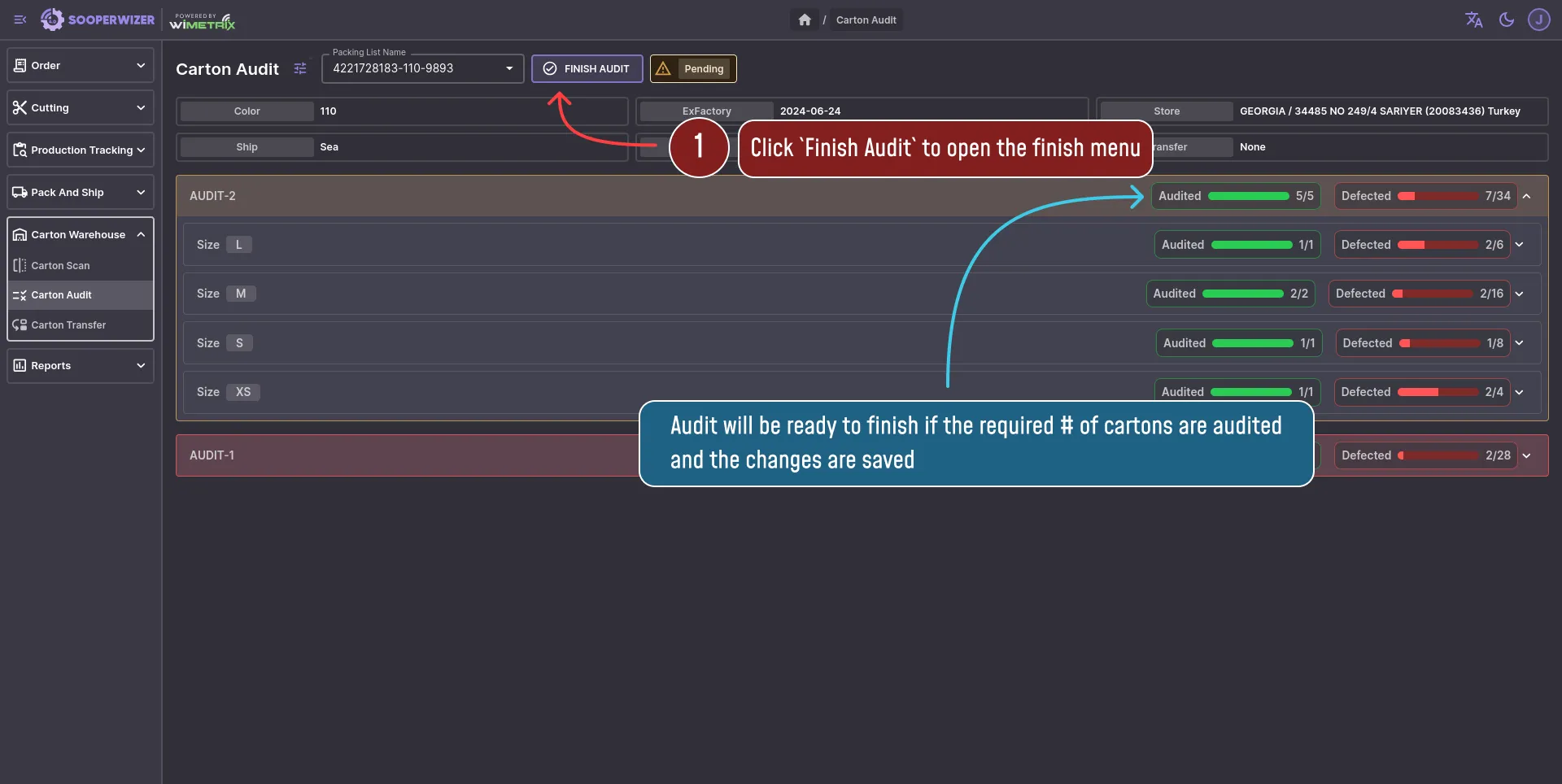

When all cartons are reviewed, click the Finish Audit button

- The finish carton audit dialog will open

- The dialog will show the sample size, defected pieces, and DHU % to help the auditor make a decision

-

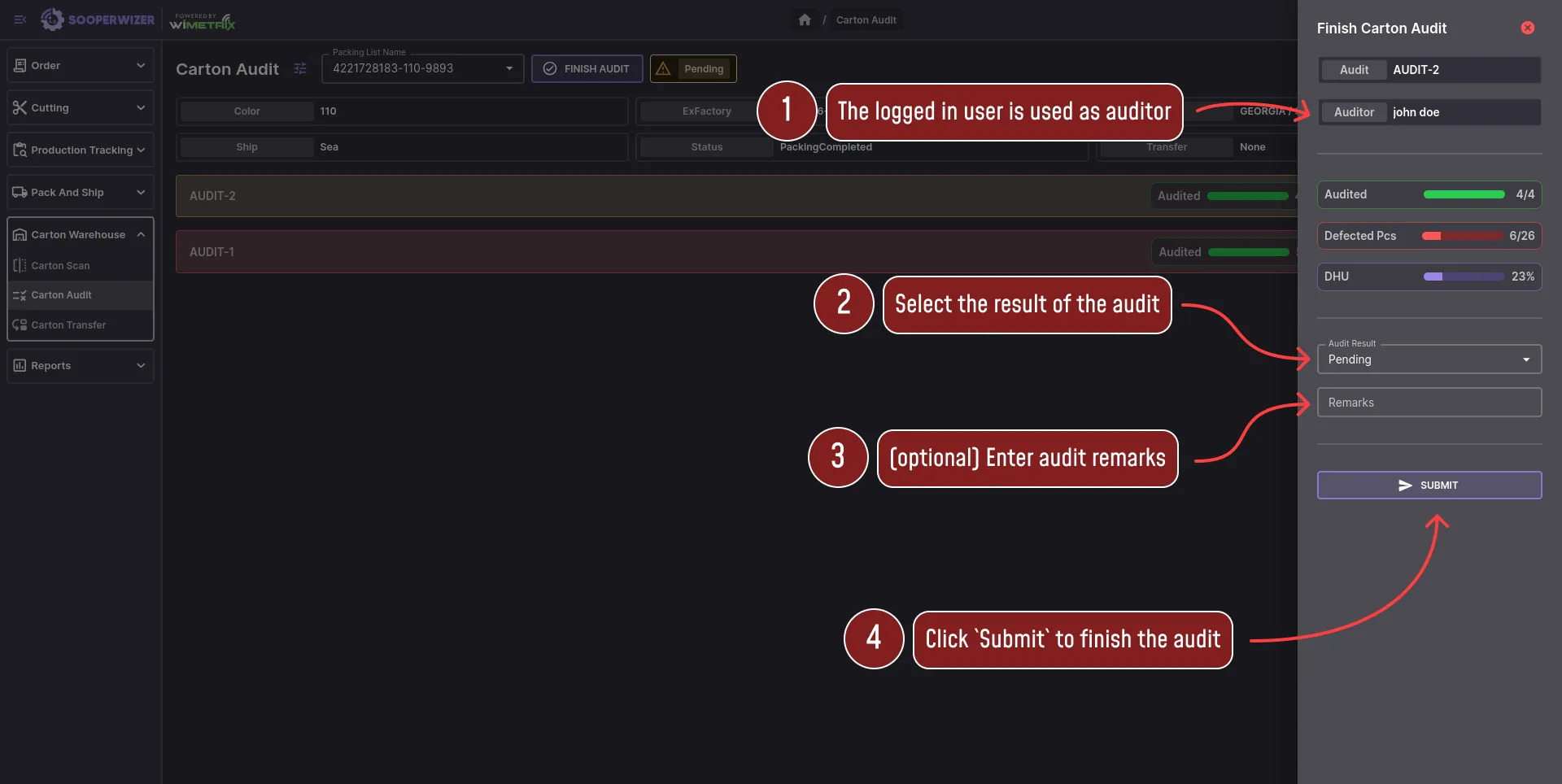

Select the carton audit status

-

(Optional) Add additional remarks for the audit

-

Click Submit to finish the audit

- In

CartonAuditSession,Auditorwill be set to the logged-in user - In

CartonAuditSession,AuditStatuswill be set to the selected status - In

CartonAuditSession,AuditDatewill be set to the current time stamp - In

CartonAuditSession,Remarkswill be set to the provided remarks - If the audit is successful, In

PrePackingList,PackStatuswill be set toPackingAudited

- In

Technical Details

Section titled “Technical Details”Available to

Section titled “Available to”adminerpcarton audit

Required Roles

Section titled “Required Roles”packing:pre_pack:getpacking:pack_job:getpacking:carton_audit:getpacking:carton_audit:post

Audit Status Enum

Section titled “Audit Status Enum”

PassandFailButReleaserepresent successful audits

Pass- Pre-Pack is ready to shipFailButRelease(FBR) - Pre-Pack is ready to shipRecheck- Needs further auditing, and/or repackingHold- Re-audit is required without repackingFail- Needs a re-audit and/or repacking

Defects per Hundred Units (DHU) Calculation

Section titled “Defects per Hundred Units (DHU) Calculation”DHU is crucial for deciding the result of the audit.

DHU Formula:

DHU = DefectPieces / TotalPieces * 100Sample Size Calculation

Section titled “Sample Size Calculation”Sample Size is used to calculate the number of cartons that need to be audited for each size.

Sample Size Formula:

if (prePackQty < 16) sampleSize = 2else if (prePackQty < 26) sampleSize = 3else if (prePackQty < 91) sampleSize = 5else if (prePackQty < 151) sampleSize = 8else if (prePackQty < 281) sampleSize = 13else if (prePackQty < 501) sampleSize = 20else if (prePackQty < 1201) sampleSize = 32else if (prePackQty < 3201) sampleSize = 50else if (prePackQty < 10001) sampleSize = 80else if (prePackQty < 35001) sampleSize = 125else if (prePackQty < 150001) sampleSize = 200else if (prePackQty < 500001) sampleSize = 315else sampleSize = 500The number of cartons that need to be audited for each size is calculated by te following formula:

cartonsToAudit = ((sampleSize / prePackQty) * sizePackQty) / 3;The value is rounded to the nearest integer.

For example:

- Size

XXLsizePackQty:150 - Size

LsizePackQty:200 - prePackQty:

150 + 200 = 350 - sampleSize:

13 - Size

XXLcartonsToAudit:((13 / 350) * 150) / 3 = 1.85 = 2 - Size

LcartonsToAudit:((13 / 350) * 200) / 3 = 2.47 = 2 - Total cartonsToAudit:

2 + 2 = 4

The following columns are shared by all tables and are therefore excluded:

CreatedAt,UpdatedAt,CreatedBy,UpdatedBy

Screenshots

Section titled “Screenshots”