Product: MEMS

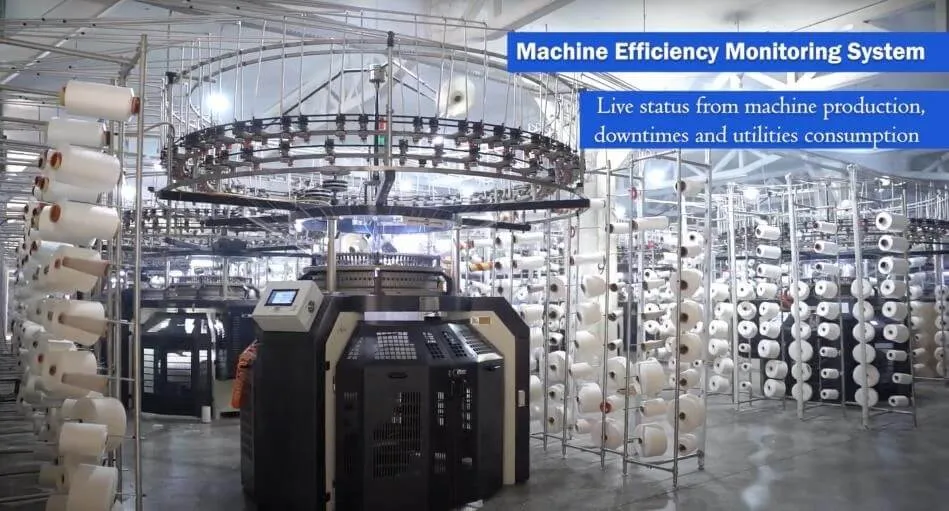

Machine Efficiency Monitoring System (MEMS) deals with Embedded software systems and IOT devices.

MEMS evaluates the performance of on-floor machines by monitoring their state utility consumption, and efficiency in real-time.

MEMS captures machine data and visualizes it across the factory in real-time through capturing data from machine PLC.

- Monitor Machine Efficiency

- Monitor Machine Utility

- Monitor Top Downtimes

- Monitor Efficient Operators

- Calculate Costing Order-wise

MEMS works on the principal of drawing electrical signals from a given machine and then decoding signals, to decide machine state.

The machine state in turn is used for monitoring efficiency.

The solutions comprise of the following layers:

- Hardware

- Signal Mapping

- Data Interface

Process Flow Diagram

Section titled “Process Flow Diagram”

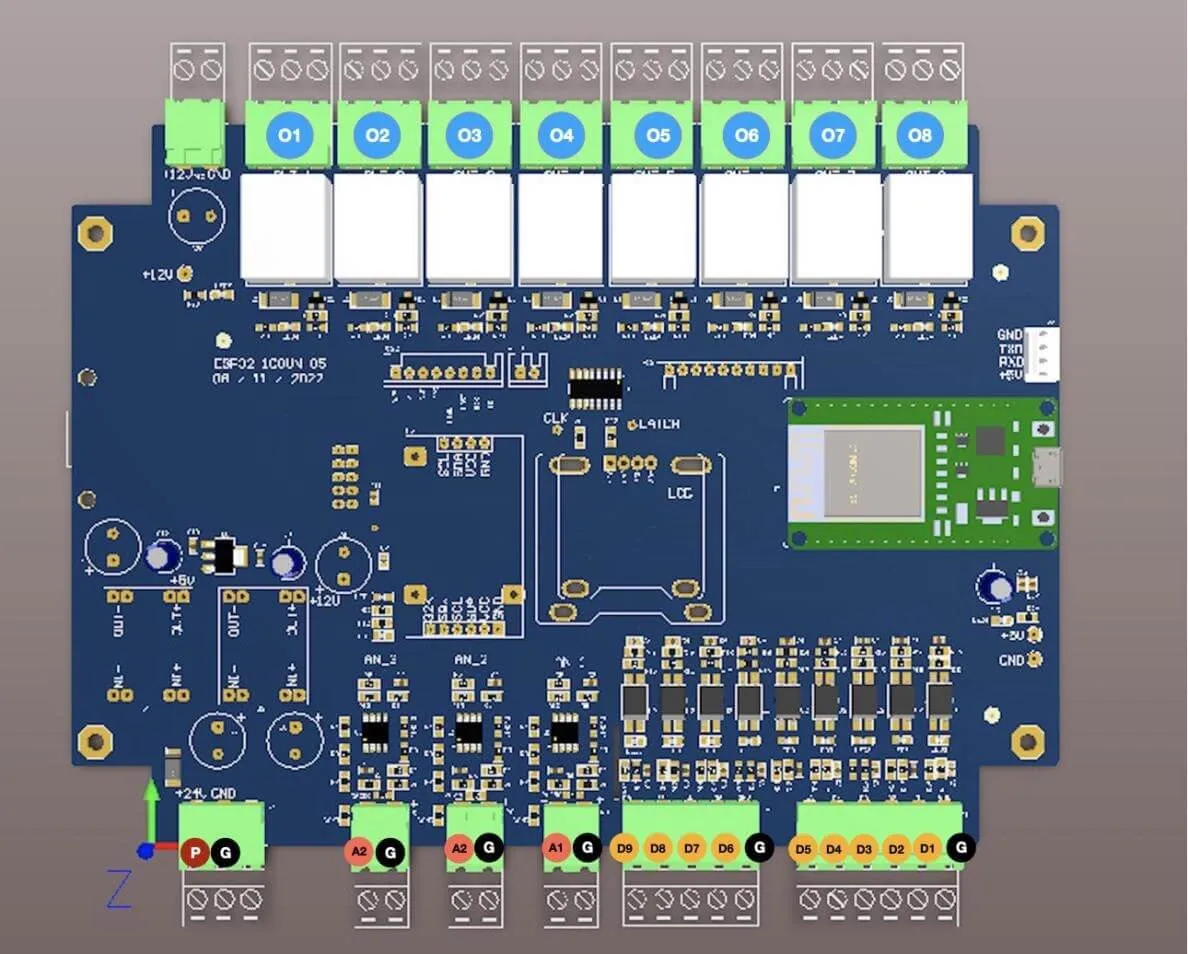

Hardware Feature Set

Section titled “Hardware Feature Set”Mother Board

Section titled “Mother Board”- Integrated RFID Reader.

- Customized PCB/Motherboard with dual-core SOC.

- ports for: 3 analog signals (0-10V or 4-20mA) .

- 9 optically isolated digital inputs High-speed digital pulse counter.

- Communication, ports (RS485/RS232).

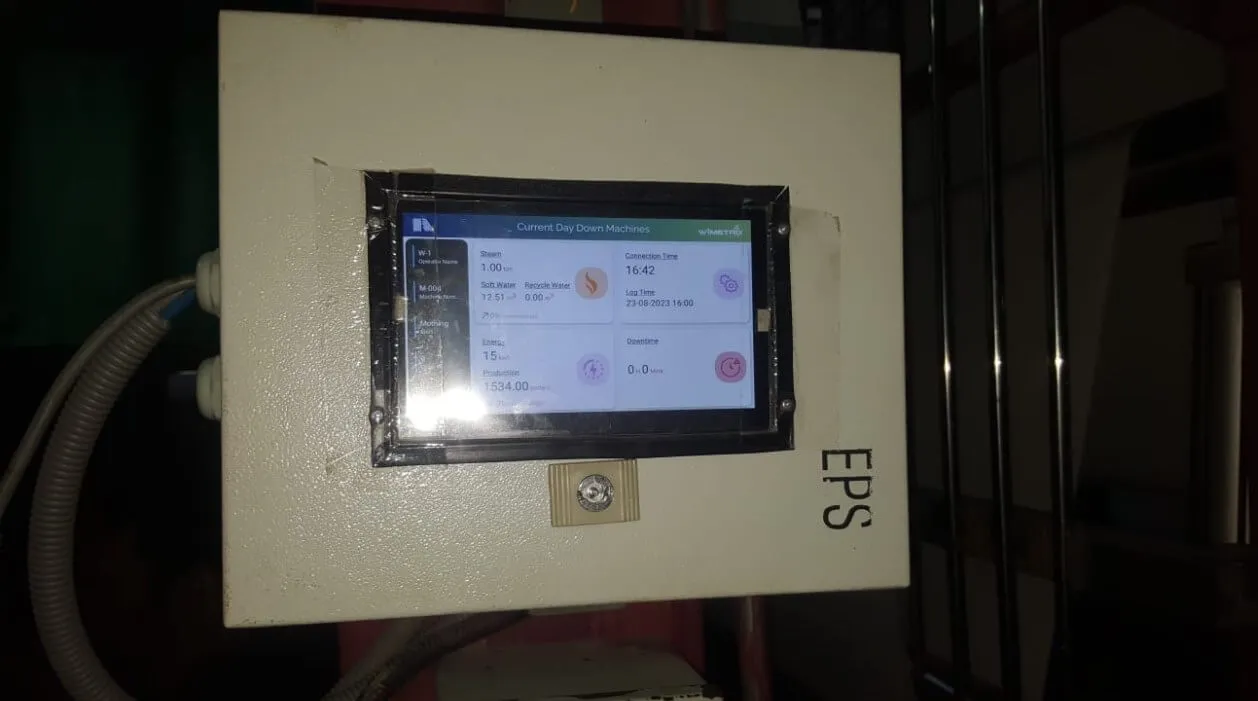

Touch Screen Android LCM

Section titled “Touch Screen Android LCM”- Android-based interface with a 10” industrial display, dual-core processor. RAM 2GB, and Support customized application.

- capable of wireless communication with the network support 2.5GHZ.

Casing

Section titled “Casing”- industrial-grade body enclosure IP5x.

- Screen Protector 3mm.

Signal Types

Section titled “Signal Types”The Board works on 3 Signal Types:

- Digital Inputs

- Analog Inputs

- Digital output

There are a total of 9 Digital Inputs in the board that can range from a minimum

of 5 Volts and a maximum of 12 Volts.

Input Mapping

Section titled “Input Mapping”- Digital Inputs

D1 /D2 /D3 /D4 /D5 /D6 /D7 /D8 /D9

- Analog Inputs

A1 /A2 /A3

- Output Signals

O1 /O2 /O3 /O4 /O5 /O6 /O7 /O8

MEMS In Action

Section titled “MEMS In Action”